Custom-made Digitizing for Embroidery: Tailored to Your Requirements

Understanding the Embroidery Digitizing Refine: Your Ultimate Guide

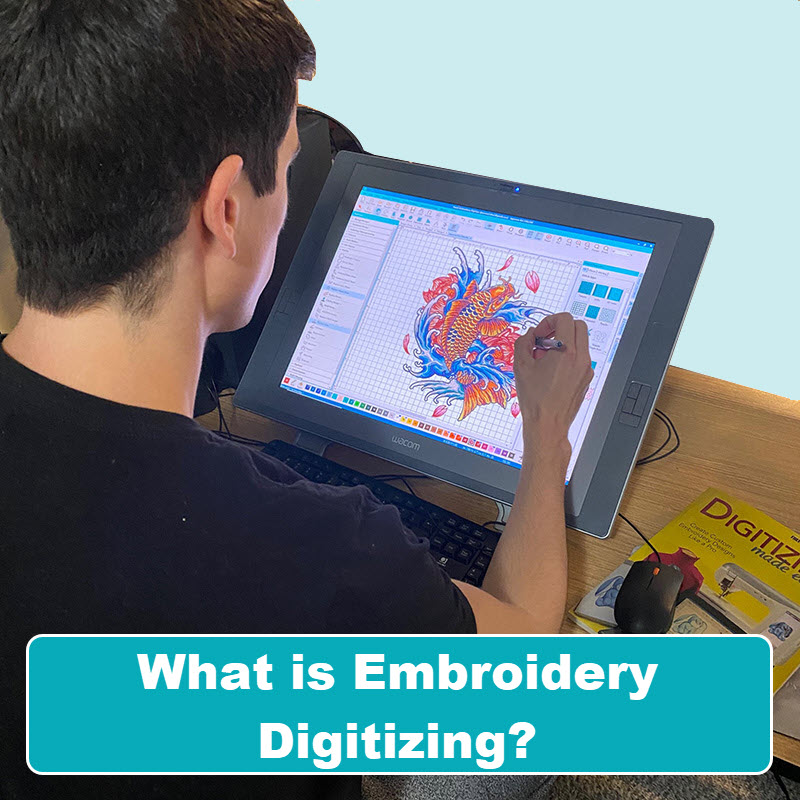

Embroidery digitizing is a thorough craft that requires precision and knowledge to convert intricate designs right into electronic formats for device needlework. As craftsmens begin on this trip to understand the embroidery digitizing process, a detailed understanding of the essentials sets the structure for quality. However, beyond the fundamental expertise lies a realm of advanced software program, specialized devices, and nuanced techniques waiting to be checked out. By delving right into the nuances of digitizing, one can unlock a world of innovative opportunities and raise their needlework jobs to brand-new heights.

Understanding Embroidery Digitizing Basics

Embroidery digitizing basics develop the structure upon which detailed styles are converted into machine-readable layouts for precise sewing. This first action in the needlework digitizing procedure is vital for ensuring that the final stitched item is a devoted representation of the original design. Understanding needlework digitizing basics involves grasping vital principles such as stitch kinds, sew instructions, density, underlay, and pull settlement.

Sew types play an important role in establishing the aesthetic and textural result of the embroidered layout. By choosing the suitable stitch type, whether it be satin, fill, or running stitch, digitizers can achieve the wanted impact and enhance the overall top quality of the embroidery. Additionally, sew instructions influences the circulation and measurement of the design, while density determines the spacing and insurance coverage of the stitches.

Moreover, underlay sewing supplies stability to the layout by protecting the fabric and preventing distortion throughout the needlework process. Pull payment is an additional crucial factor to consider to counteract the all-natural propensity of fabric to contract when sewn. Grasping these embroidery digitizing basics is fundamental for developing professional-quality embroidered items.

Picking the Right Digitizing Software

Choosing the ideal digitizing software is an important choice that significantly affects the effectiveness and top quality of the needlework digitizing process. Digitizing for Embroidery. When choosing the best digitizing software program, it is necessary to consider factors such as the intricacy of styles you prepare to develop, the user-friendliness of the software program, the degree of customer support used, and the compatibility with your needlework device

There are various digitizing software alternatives available in the market, ranging from basic programs for beginners to advanced software for professional digitizers. Some popular selections consist of Wilcom EmbroideryStudio, Hatch Needlework Software Program, and PulseID. These software program plans supply a large range of devices and functions to help you create intricate designs with convenience.

Prior to choosing, it is suggested to discover the various software application choices through free tests or demonstrations to figure out which one finest suits your demands. In addition, checking out evaluations and seeking recommendations from skilled digitizers can provide beneficial understandings into the strengths and weak points of each software application bundle (Digitizing for Embroidery). By carefully evaluating your needs and comparing the features of various digitizing software application, you can make an enlightened option that enhances your needlework digitizing process

Digitizing Tools and Strategies

Optimizing Style Setup for Needlework

Grasping the complexities of style settings is essential in accomplishing optimal lead to the embroidery digitizing procedure, structure upon the foundation laid by comprehending digitizing tools and techniques. When optimizing design setups for needlework, it is vital to think about aspects such as stitch type, density, underlay, draw settlement, and registration. Stitch type option influences the total look and feel of the layout, with choices like satin, fill, and running stitches supplying various structures and effects. Thickness refers to the spacing and density of stitches, impacting the design's insurance coverage and longevity. Correct rug sewing offers security and stops material distortion, specifically for complicated styles or on elastic products. Draw settlement readjusts for material check stretch during sewing, making sure accurate layout replication. Enrollment settings straighten different elements of the style accurately, keeping general layout stability. By fine-tuning these style setups, embroiderers can boost the quality and precision of their stitched developments.

Troubleshooting Common Digitizing Issues

When encountering typical digitizing concerns during the needlework process, it is vital to understand the origin causes and apply efficient solutions immediately. One common problem is stitch thickness concerns, where stitches may be as well thick, creating the fabric to tighten, or also thin, resulting in spaces in the layout. Adjusting the stitch density setups in the digitizing software program can help solve this concern.

Another regular difficulty is string breaks throughout the embroidery process. This can occur because of numerous factors Visit This Link such as wrong tension settings, dull needles, or utilizing low-grade string. Making certain appropriate upkeep of the needlework machine, including regular needle changes and tension modifications, can lessen the incident of string breaks.

In addition, layout enrollment mistakes can cause misaligned components within the needlework layout. Checking the design alignment in the digitizing software program and making essential changes prior to stitching can assist in avoiding this issue. By dealing with these common digitizing issues promptly and effectively, you can ensure a smoother needlework procedure and high-quality finished items.

Verdict

To conclude, understanding the needlework digitizing procedure needs a solid understanding of the basics, the right selection of software program, and understanding of tools and techniques. Maximizing style settings and troubleshooting usual digitizing problems are important steps in ensuring high-grade needlework outcomes. By complying with these steps faithfully, one can accomplish precision and performance in the digitizing process.